NEW METALS is expanding its service network to offer Parts Fabrication as part of its efforts to broaden its market and strengthen relationships with current and potential customers.

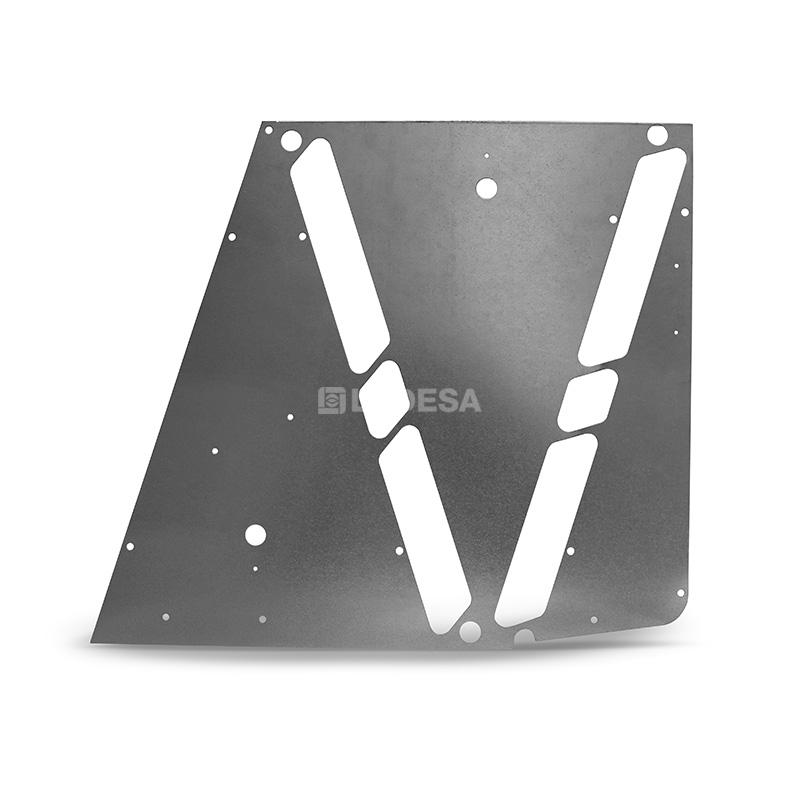

So, what exactly is Parts Fabrication? We provide added value by manufacturing metal parts and pieces, from OEM components to finished products. And we don’t just work with expanded metal, our engineering team works closely with clients to develop custom pieces according to their specific needs using materials such as steel, aluminum, and other metals.

We offer various processes, such as bending, assembly, laser cutting, and stamping. For example, sheet and plate bending is a deformation process that gives the material the desired shape without cutting it. This process is carried out using a press and punch and causes a slight thinning in the bending zone.

We provide solutions for various industries, including the automotive industry. Laser cutting is one of the best cutting processes due to its precision and speed, using thermal energy to separate metal sheets into equal or uneven cuts and special shapes. In the stamping process, irregular cuts or grooves are made to create designs, and special dies are fabricated according to the equipment’s plan and requirements.

In addition to our machinery and capabilities, NEW METALS has an engineering department that provides quick and effective responses for prototype manufacturing, technical support for design, and manufacturing analysis to find lasting solutions.

We are ready to work with you to speed up your manufacturing processes with our Parts Fabrication line. We have the equipment, experience, and strength that the market requires.